Exporting industrial machinery requires proper planning, documentation, compliance, and logistics coordination. The global demand for…

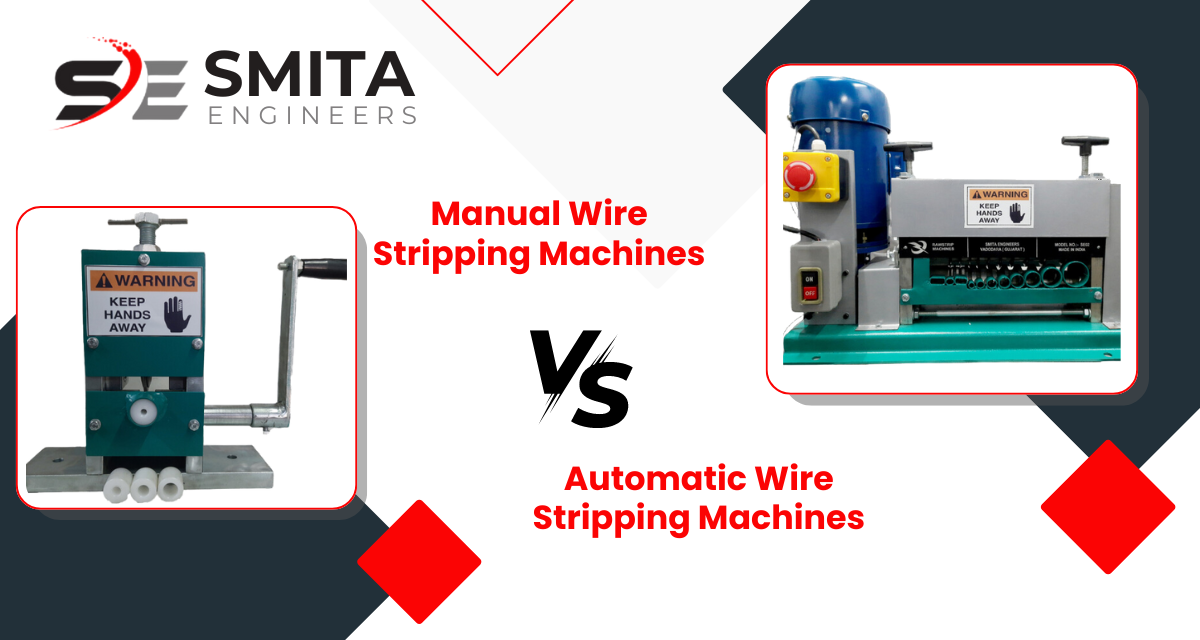

When it comes to working with wires, stripping them cleanly and efficiently is essential for various industries. Wire stripping machines help remove the insulation from wires, making them ready for further processing. But which is better: a manual or automatic wire stripping machine? Let’s dive into the differences and find out which option best suits your needs.

Comparison of Manual vs. Automatic Wire Stripping Machines

Certainly! Here’s a comparison between manual and automatic wire stripping machines in a table format:

| Feature | Manual Wire Stripping Machines | Automatic Wire Stripping Machines |

| Cost | More affordable, suitable for small businesses | Higher upfront cost, but better for high-volume operations |

| Efficiency | Slower process, requires manual effort | Faster, high-speed operation, saves time and effort |

| Precision | Depends on user skill, may lead to inconsistent results | Offers consistent and precise wire stripping every time |

| Maintenance | Low maintenance, fewer moving parts | Requires regular maintenance for optimal performance |

| Versatility | Can handle a variety of wire sizes, but slower for large volumes | Handles a wide range of wire sizes quickly and efficiently |

| Best For | Small-scale or occasional projects | Large-scale, high-volume wire stripping operations |

| Labor Requirement | Requires significant manual labour | Minimal labour needed, automated process |

| Durability | Durable due to simpler construction | Durable but requires more upkeep due to complex mechanisms |

| Application Suitability | Suitable for hobbyists, small workshops | Ideal for industrial applications, large workshops, recycling |

Smita Engineers offers both manual and automatic wire stripping machines to cater to different operational needs, ensuring you can choose the best option based on your project requirements.

Which One Should You Choose?

The choice between manual and automatic wire stripping machines largely depends on your operational needs. If you are a small business or working on occasional projects, a manual machine may be more than enough to get the job done. However, an automatic machine would be a more efficient investment if you run a large-scale operation or require high-speed and precision stripping.

Smita Engineers, a leading wire stripping machine manufacturer, offers both manual and automatic wire stripping solutions tailored to your specific needs. Whether you’re looking for affordability and simplicity or speed and precision, Smita Engineers has the right machine for you.

FAQs

Which machine is better for high-volume work?

Automatic wire stripping machines are ideal for high-volume operations, offering speed and precision.

Can Smita Engineers’ machines handle different wire sizes?

Yes, our machines are designed to handle a wide range of wire sizes and types.

Do Smita Engineers’ machines require maintenance?

Manual machines need minimal maintenance, while automatic machines require regular upkeep for optimal performance.

How can I order a wire stripping machine from Smita Engineers?

You can place an order by contacting us directly through our website or phone.

Are your machines suitable for industrial applications?

Absolutely! Smita Engineers specializes in providing high-performance wire stripping machines that are built for industrial use. Our automatic models are particularly well-suited for large-scale operations where efficiency and precision are critical.

Conclusion

In conclusion, manual wire stripping machines are suitable for smaller operations and those looking for cost-effective solutions. However, investing in an automatic machine is the way to go if you need to scale your operations or improve productivity. Smita Engineers is ready to help you make the best choice for your business.